Revolutionising Style and Safety: ALPOLIC™ NC/A1 Recladding of Trilogi Apartments, Melbourne

When Melbourne’s Trilogi Apartments faced the urgent need to replace hazardous cladding, they turned to ALPOLIC™ NC/A1 for a solution that blends unmatched safety with stunning design. Explore how this advanced aluminium composite cladding met rigorous safety standards and elevated the building’s aesthetic.

The Trilogi Apartments in Melbourne faced a critical safety issue when it was discovered that their existing cladding was combustible. Under Australian safety regulations, the body corporate was required to replace the cladding with a product that satisfied NCC compliance requirements. After thorough evaluation, ALPOLIC™ NC/A1 was selected for its superior properties, fulfilling the recladding project’s safety and aesthetic requirements.

ALPOLIC™ NC/A1 is renowned as the safest, most versatile aluminium composite cladding available on the market, successfully completing the required testing to meet the DtS criteria under the National Construction Code. Its superior flatness, durability, and wide range of colours and finishes, combined with an industry-leading 20-year unconditional full replacement warranty backed by Mitsubishi Chemical Infratec Co., Ltd, made it the ideal choice for the Trilogi Apartments project.

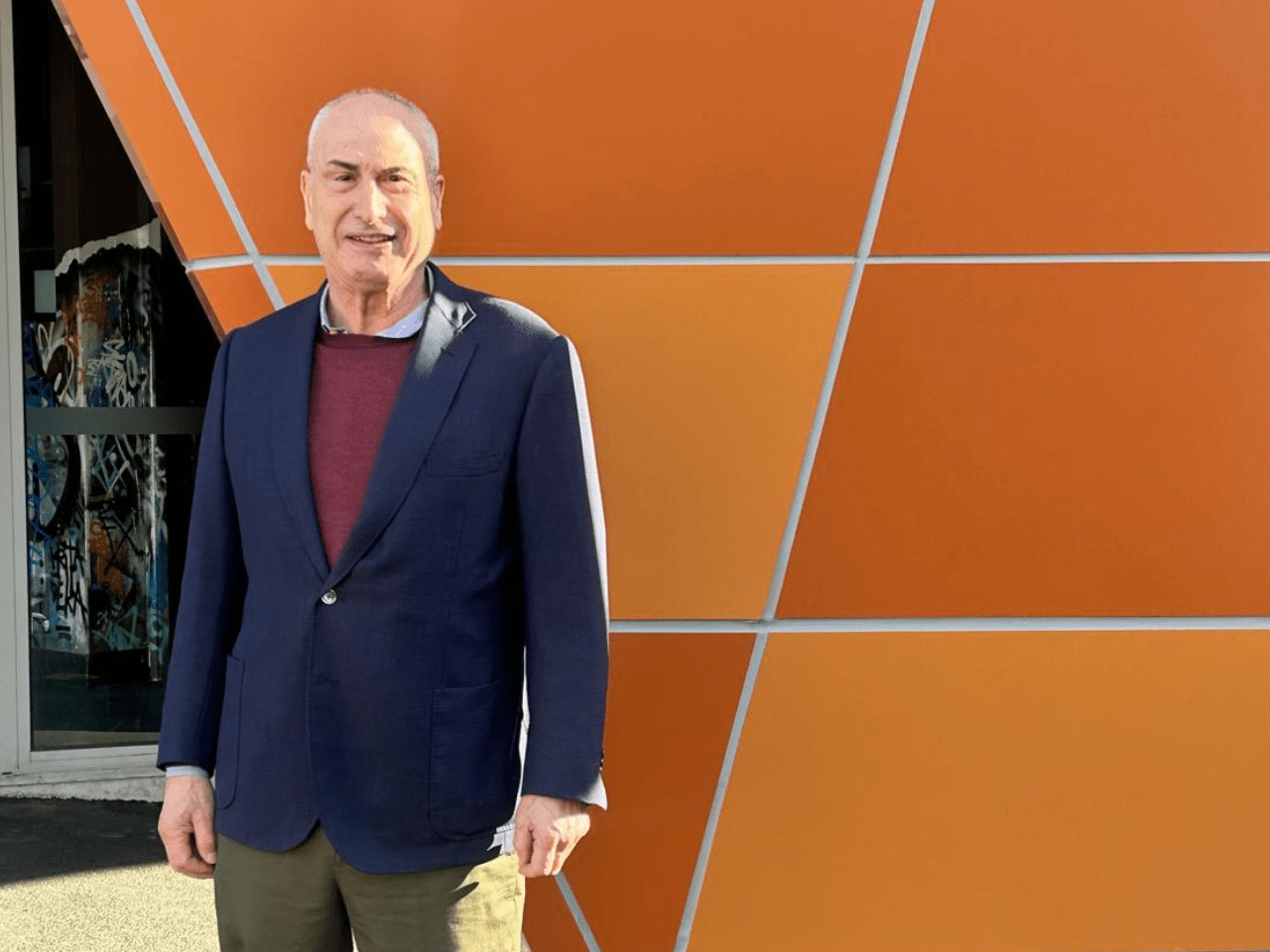

Dr. Jonathan Barnett, Fire Safety Engineer and Chairman of the Owners Corporation, played a pivotal role in the selection process. He stated, “When we discovered the presence of combustible cladding, we needed a reliable and safe solution. I was pleased with ALPOLIC™ NC/A1’s comprehensive warranty and extensive test reports which not only met stringent safety standards but also provided long-term peace of mind for our residents.”

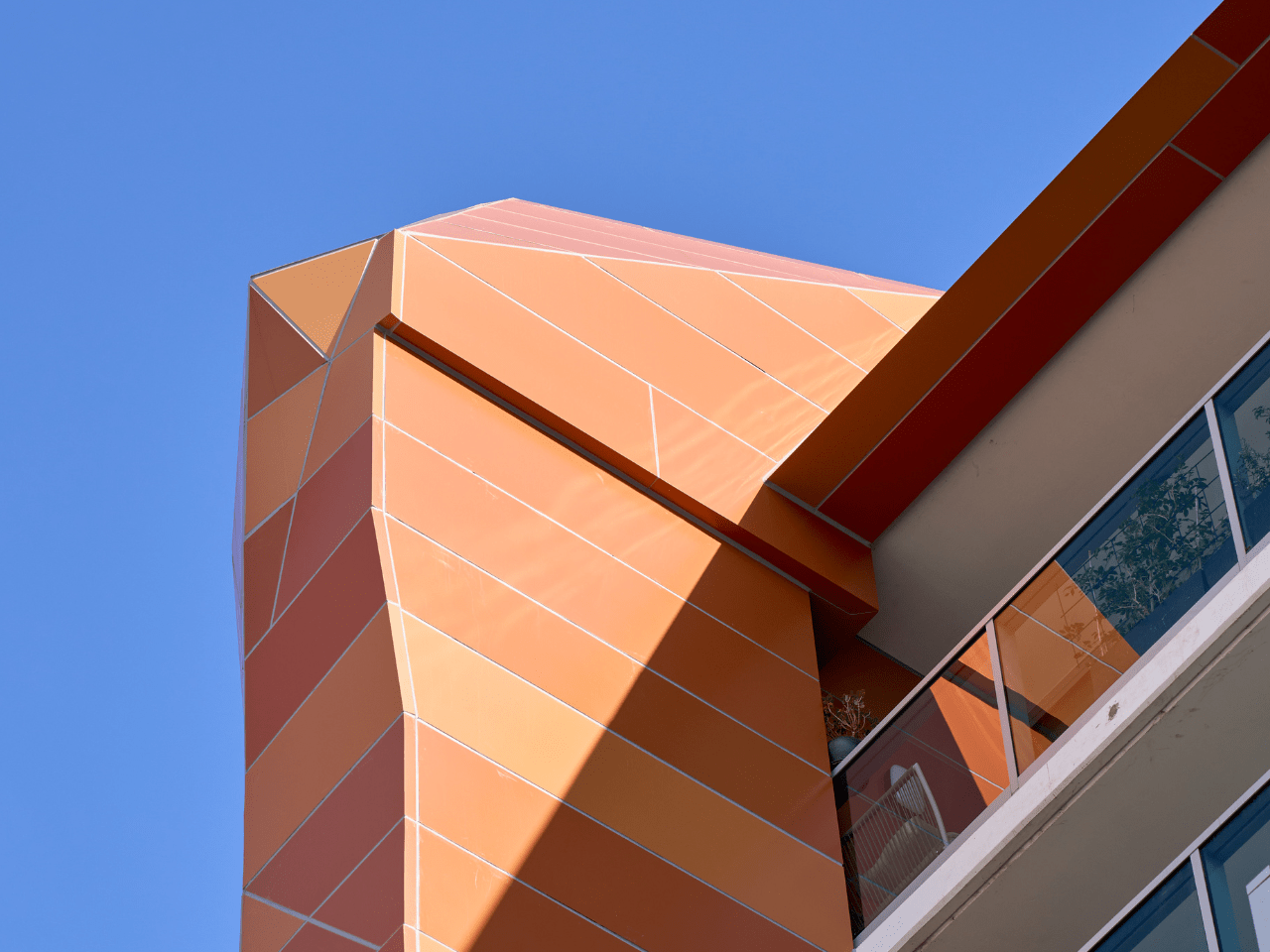

The project was managed under Cladding Safety Victoria’s replacement program, which involved appointing an independent project manager to oversee the recladding process. Although solid aluminium sheets were initially considered, ALPOLIC™ NC/A1 was chosen due to its superior rigidity and aesthetic appeal. Dr. Barnett highlighted, “Solid aluminium sheets can deform under the sun’s heat, creating a rippled appearance. ALPOLIC™ NC/A1, on the other hand, offers exceptional flatness and maintains its structural integrity under extreme weather conditions.”

Network Architectural (NA), supplier of ALPOLIC™ NC/A1, provided extensive technical support throughout the project. Dr. Barnett praised their involvement, saying, “Network Architectural visited the site regularly, ensuring that everything was progressing smoothly. Their expertise and support were invaluable, particularly in achieving the perfect colour match with the existing cladding.”

The cladding installation was carried out by ACA Cladding, who are extremely experienced in working with various cladding materials. This was their first project using ALPOLIC™ NC/A1, and they were impressed by its performance. “ALPOLIC™ NC/A1 is 4mm thick, making it more rigid and easier to handle compared to other materials,” noted Samuel Harkness, Construction Manager ACA Cladding. “The colour consistency and finish were excellent, and the 20-year warranty provided an added layer of assurance.”

The installation process required meticulous planning due to the need to replicate the original colour scheme. The use of drones by the builder, SJ Higgins, facilitated precise planning and layout. “The collaboration between Network Architectural, SJ Higgins, and our team ensured a smooth workflow,” Samuel added. “Despite the initial learning curve with the thicker material, the final result was impressive, and we would definitely use ALPOLIC™ NC/A1 for future projects.”

The Trilogi Apartments project exemplifies the numerous benefits of ALPOLIC™ NC/A1:

- Safety and Compliance: ALPOLIC™ NC/A1 meets all Australian Government testing requirements, providing a DtS non-combustible cladding solution. It is the safest and most tested aluminium cladding on the market.

- Superior Flatness and Durability: The cladding maintains its flatness and structural integrity under extreme weather conditions, preventing deformation and ensuring a long-lasting, aesthetically pleasing finish.

- Wide Range of Colours and Finishes: With the largest selection of colours and finishes available, ALPOLIC™ NC/A1 allows for precise colour matching, maintaining the visual integrity of the building.

- Industry-Leading Warranty: The 20-year unconditional full replacement warranty, backed by Mitsubishi Chemical Infratec Co., Ltd, provides unmatched peace of mind, covering both product and installation.

- Environmental Responsibility: ALPOLIC™ NC/A1 has an Environmental Product Declaration (EPD) produced by GECA, reflecting its commitment to responsible design without compromising quality.

- Low Maintenance: Featuring Lumiflon FEVE coating technology, ALPOLIC™ NC/A1 offers exceptional UV, hail, and corrosion resistance, maintaining its colour and appearance with minimal maintenance.

The Trilogi Apartments project in Melbourne stands as a testament to the exceptional qualities of ALPOLIC™ NC/A1 aluminium composite cladding. From its unmatched safety and compliance standards to its superior aesthetic and durability, ALPOLIC™ NC/A1 provided the perfect solution for this complex recladding project. The collaboration between the owners, project managers, suppliers, and installers ensured a successful outcome, showcasing the benefits of choosing a high-quality, reliable cladding product for building safety and visual appeal.

For architects, builders and owners, ALPOLIC™ NC/A1 offers a proven, dependable solution that meets the highest safety standards while delivering exceptional performance and aesthetic versatility.

So, if you need help with your recladding project, Network Architectural not only offers the most tested, sustainable DtS non-combustible recladding solution, we also have a team of dedicated experts at the forefront of providing up-to-date guidance and advice. We work with accredited fabricators and installers and can provide technical expertise to achieve the best outcome for your project no matter how big or small.

Our highly experienced team will work closely with you at all stages of your recladding project from initial advice, project management through to project completion.

For advice or guidance on your recladding project contact us today.

Related Articles

Recladding with Confidence: How the University of Sydney Delivered a Future Proof Façade

When the University of Sydney reclad the Charles Perkins Centre, compliance alone was not enough. This article explores how a premium, maintenance-free façade solution delivered long-term confidence, design integrity and fire compliance, restoring one of the campus’s most recognisable buildings with a future-proof architectural outcome.

Top 5 Residential Facade Trends in 2026 – and How ALPOLIC™ Brings Them to Life

Australian residential facades are evolving, with 2026 trends favouring clean lines, layered materials, natural finishes and bold colour accents. This article explores the top five residential façade trends shaping contemporary homes and how material choice plays a key role in balancing design expression, durability, sustainability and long-term performance.

How ALPOLIC™ Became the National Standard for Toyota Dealerships

Toyota’s nationwide brand consistency relies on materials that look flawless, perform reliably and meet strict compliance standards. This article explores why ALPOLIC™ has been Toyota’s trusted façade and signage solution for more than two decades, and how its durability, colour stability and technical support have cemented it as the national standard across TMCA dealerships.