Metal ceilings are common in many different types of buildings and spaces today, especially commercial projects due to the high-quality appearance and functional benefits they offer.

Made from a versatile and robust material, metal ceilings can be easily customised in a variety of colours, sizes, shapes, finishes and styles to cater to the unique requirements of your project. They also often come with acoustic properties, fire resistance characteristics and integrated lighting solutions that improve the safety and comfort of commercial spaces.

Beyond these advantages, metal ceilings stand out as an excellent choice in construction projects because they enable designers and other building professionals like you

to promote sustainable practices.

This is particularly crucial in today’s business landscape, where people have become more conscious of environmental and social issues.

In this article, we will explore how metal ceilings can contribute to the success of your sustainability initiatives.

The misconceptions about metal ceilings sustainability

There are a few fallacies about the sustainability of metal ceilings which often cause Architects and Builders to hesitate about using them in commercial projects.

Let’s address these metal ceiling misconceptions one by one.

Misconception 1: Metal ceilings are not environmentally friendly because of their energy-intensive production.

Most people assume that metal ceilings have a high carbon footprint due to the significant amount of energy and resources required for their production.

However, due to technological advancements, manufacturing companies have become far more energy-efficient and eco-friendly with their processes.

At Network Architectural, we take immense pride in being the exclusive Australian distributor of durlum metal ceilings.

All durlum metal ceilings are produced using environmentally compatible processes and technologies. In addition, these metal ceiling systems satisfy all the VOC emission requirements defined in Green Building Standards.

Misconception 2: Metal ceilings contribute to the depletion of natural resources.

Metal is a recyclable material – meaning, metal ceilings can be repurposed after their initial use. This gives you and your clients the opportunity to reduce waste and conserve natural resources.

The durlum metal ceilings we supply at Network Architectural also have long lifespans, so they don’t have to be frequently repaired or replaced.

Misconception 3: Metal ceilings are prone to corrosion and water-related damage, leading to higher maintenance costs.

Quality metal ceilings are now treated to resist corrosion and withstand harsh environmental conditions.

In fact, our durlum metal ceilings can endure fluctuations in temperature and humidity without any risk of sagging, warping or becoming otherwise compromised. They are also easily cleaned with household-grade products thus reducing the potential growth of mould and mildew.

Equipped with metal ceilings that are engineered to last, you can now significantly minimise maintenance costs, making these a longer-term sustainable choice.

Sustainability: the long-term advantage of using metal ceilings

By using metal ceiling products to enhance commercial spaces, you can unleash your creativity and transform your design vision into an outstanding reality.

But what really makes metal ceilings the sustainable choice for your project is the long-term advantages they offer.

Here’s how they enable Architects, Designers and Building Professionals to facilitate sustainable practices:

-

Metal ceilings are sustainable because they are durable.

Metal is a robust and sturdy material, so rest assured that metal ceilings can withstand rough handling, strong impacts, as well as other challenging environmental conditions.

At Network Architectural, our metal ceiling solutions are all fire-resistant and compliant with Australian standards.

As metal ceilings are durable, they are also less likely to deteriorate or get damaged during their service life. This minimises and potentially eradicates the total energy required to manufacture, transport and install replacement ceilings for your project in the future.

-

Metal ceilings are sustainable because they are flexible.

Metal ceilings can be tailored to meet both your functional needs and aesthetic vision.

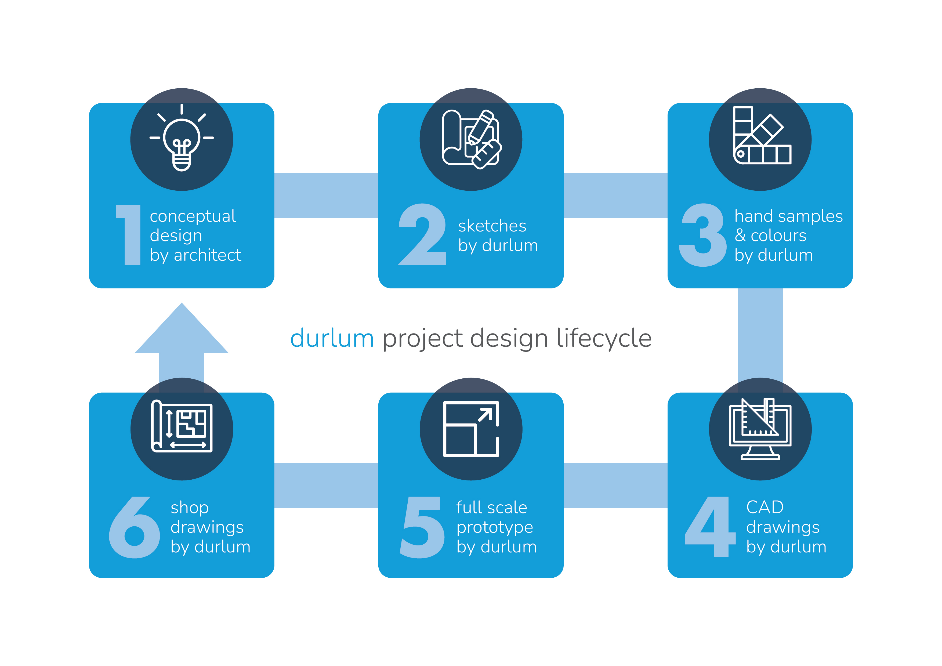

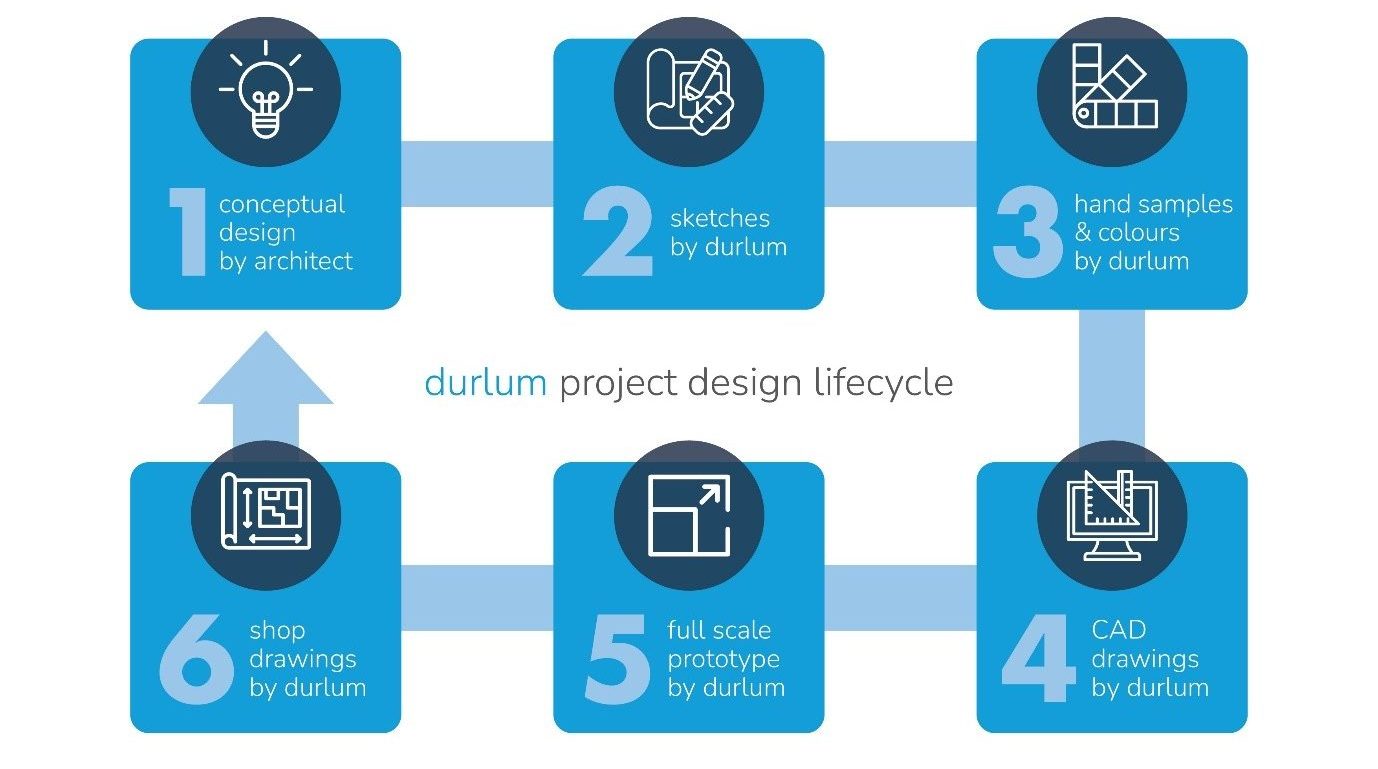

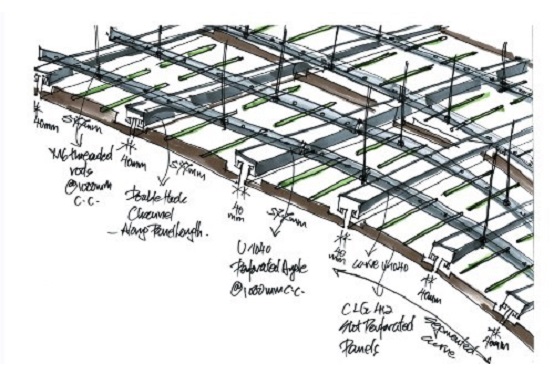

In fact, we have an in-house design service and technical team at Network Architectural to help you transform commercial spaces – regardless of whether you want the metal ceiling to be curved, faceted or flat in a timber look. We also provide designs and colour samples to meet the specific needs of your project.

Our metal ceiling solutions can also integrate with energy-efficient lighting, heating, cooling and ventilation systems, as well as provide excellent acoustics – all of which contribute to the comfort and sustainability of your commercial building by improving the well-being of its occupants.

All of this makes metal ceiling products a valuable investment as they not only make your project visually captivating but also allow you to preserve resources, reduce landfill waste and create healthier commercial spaces.

Durlum metal ceilings can help you achieve your sustainability goals

Network Architectural is your trusted partner for innovative ceiling solutions, delivering high-quality ceiling solutions like durlum metal ceilings.

These durlum metal ceiling products are equipped with Environmental Product Declarations (EPDs), which provide you with information about the properties of ceiling products and their environmental impacts over their life cycles. With EPDs, you can approach your commercial projects much more sustainably.

The durlum brand also has Green Building initiatives – including designing their ceiling products to reduce energy consumption in buildings. Furthermore, the company has been successfully certified according to the international environmental management standard ISO 14001, as well as the energy management standard, ISO 50001.

At Network Architectural, we also hold a GlobalGreenTagCert™ GreenRate™ Level A certification in Australia.

Ready to use sustainable metal ceilings in your next project?

Whether you have more questions about metal ceiling products or are looking for the right bespoke metal ceiling solutions for your project, we’ve got you covered.

Just reach out to us – our expert metal ceiling team can help you achieve the results you’re after.

As always, it’s best to seek the expertise of a trusted and well-established Australian ceiling supplier that can provide you with the highest standard of products.

At Network Architectural, we look forward to becoming your trusted partner for all your building and construction projects.

Hail damage Brisbane CBD, QLD

Hail damage Brisbane CBD, QLD Hail damage Newcastle, NSW (Photo credit: ACLAD)

Hail damage Newcastle, NSW (Photo credit: ACLAD)