As an Architect or Builder, your passion lies in crafting exceptional physical spaces that are not only functional but also visually captivating.

To enhance a property’s aesthetic appeal and value, you could consider integrating a bespoke metal ceiling into your design.

Fortunately, when it comes to bespoke metal ceilings, the sky’s the limit. High-quality metal ceilings can be customised in terms of design patterns, shapes, sizes, finishes and even functional requirements to achieve the vision of your project.

In this article, we’ll explore the benefits of bespoke metal ceilings and when you might use them. We’ll also provide insights into choosing the right metal ceiling products to ensure your bespoke ceiling project truly stands out.

What are bespoke metal ceilings?

Bespoke metal ceilings are metal ceiling solutions that have been uniquely fabricated to meet the specific design, aesthetics and functional requirements of your project.

Compared with off-the-shelf standard modular metal ceilings, bespoke metal ceilings offer the ultimate design flexibility; the limit really is your imagination. They can be easily tailored and seamlessly integrated with other architectural elements to complement the overall style, theme and interior of any property.

Why metal ceilings?

Today, metal ceilings are a popular choice for Architects and Builders alike. Here are the main reasons why:

- Durability – Metal ceilings are known to be highly robust, and capable of withstanding water damage and other harsh environmental conditions. They are easier to maintain and clean and have a longer lifespan than other materials.

- Versatility – There are various metal ceiling options available for simple or complex applications, ranging from perforated metal ceiling panels to mesh ceilings, baffle ceilings, open-cell ceilings, acoustic ceilings and suspended ceilings.

- Acoustics

- Customisation

What are the common types of metal ceilings?

There are 3 main materials used for metal ceilings.

- Aluminium Metal Ceilings.

Aluminium metal ceilings are crafted from lightweight aluminium material, so they are easily customised into various shapes, patterns and textures. They also offer unparalleled flexibility, durability and corrosion resistance, making them suitable for both indoor and outdoor applications.

- Steel Metal Ceilings

Steel metal ceilings are sturdy, cost-effective and long-lasting, making them ideal materials for physically demanding environments. These steel bespoke metal ceilings can also provide excellent acoustic and fire-resistant properties.

- Stainless Steel Metal Ceilings

Known for their distinct reflective surface, stainless steel metal ceilings offer a sleek and modern look. Available in a range of surface finishes from polished mirror to matt, these panels can also incorporate perforations, patterns and textures.

Each type of metal ceiling has its own advantages; it’s up to you to choose the one that aligns best with your project’s design and functional requirements.

Just keep in mind:

Choosing the right ceiling product is essential to ensure that your project’s aesthetic goals, durability needs, maintenance considerations and specific environmental conditions are perfectly met.

How to choose the right product for your bespoke metal ceiling

As your partner in high-quality ceiling solutions, our consultative team at Network Architectural is committed to equipping you with industry-leading brands and products that can transform your design vision into an outstanding reality.

This is why we take pride in being the exclusive distributor of in Australia: the optimal choice for bespoke metal ceilings that meet both the functional needs and distinctive aesthetic requirements of any project.

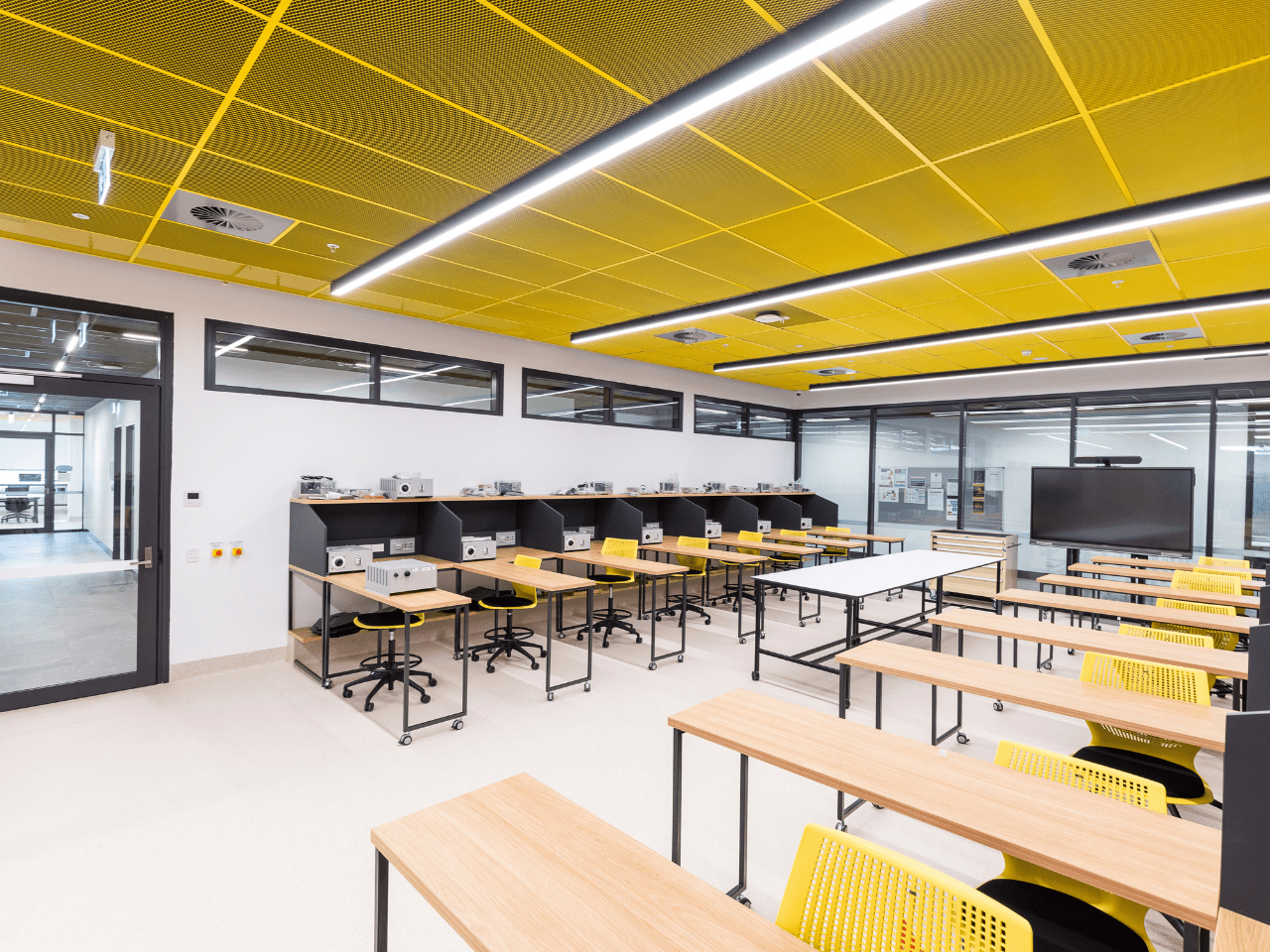

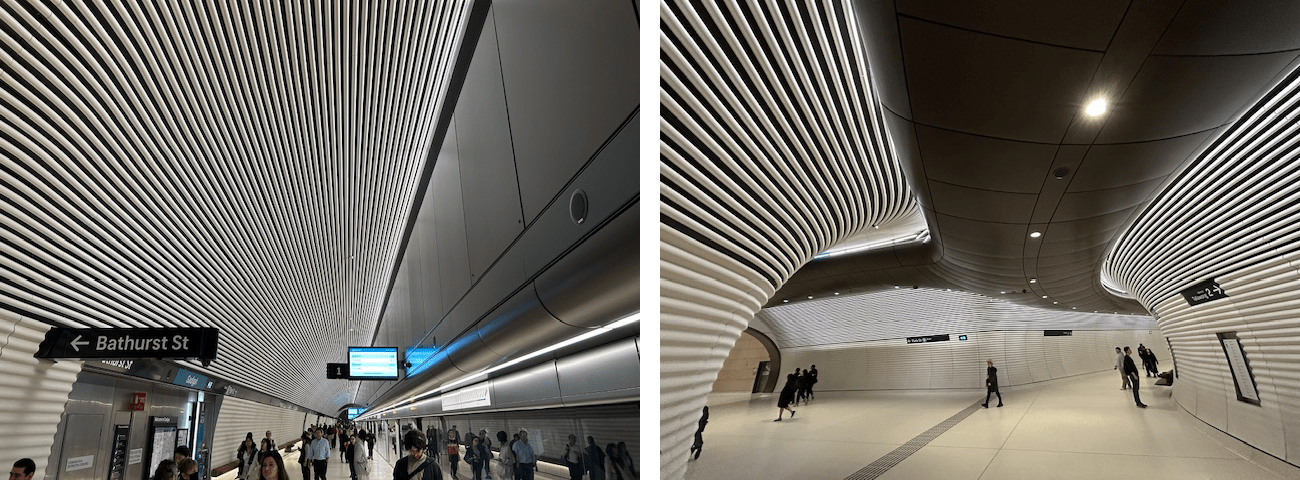

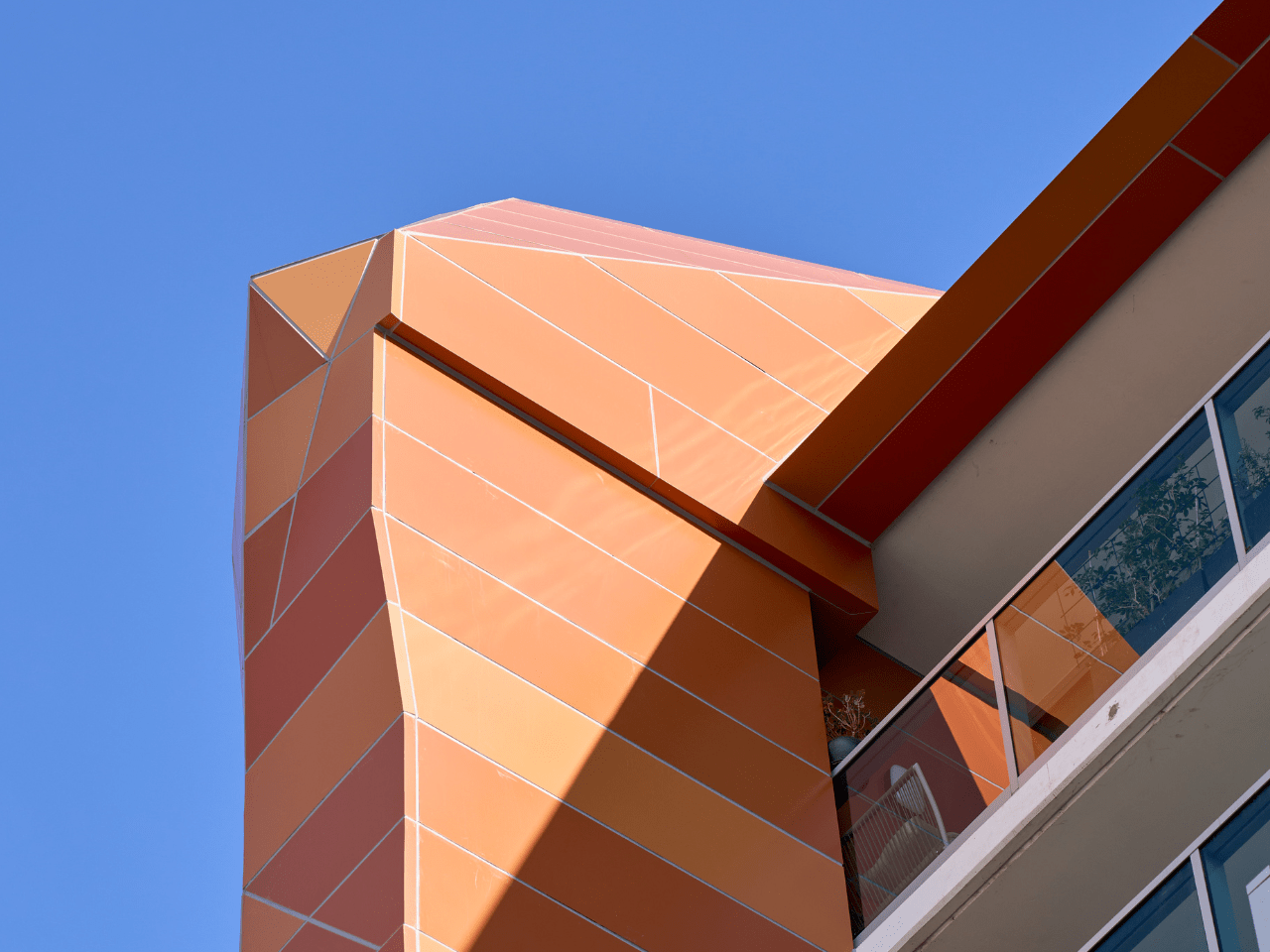

durlum metal ceilings are versatile and available in a wide range of sizes, shapes, finishes, effects, and colours. They also offer a number of integrated lighting solutions to choose from.

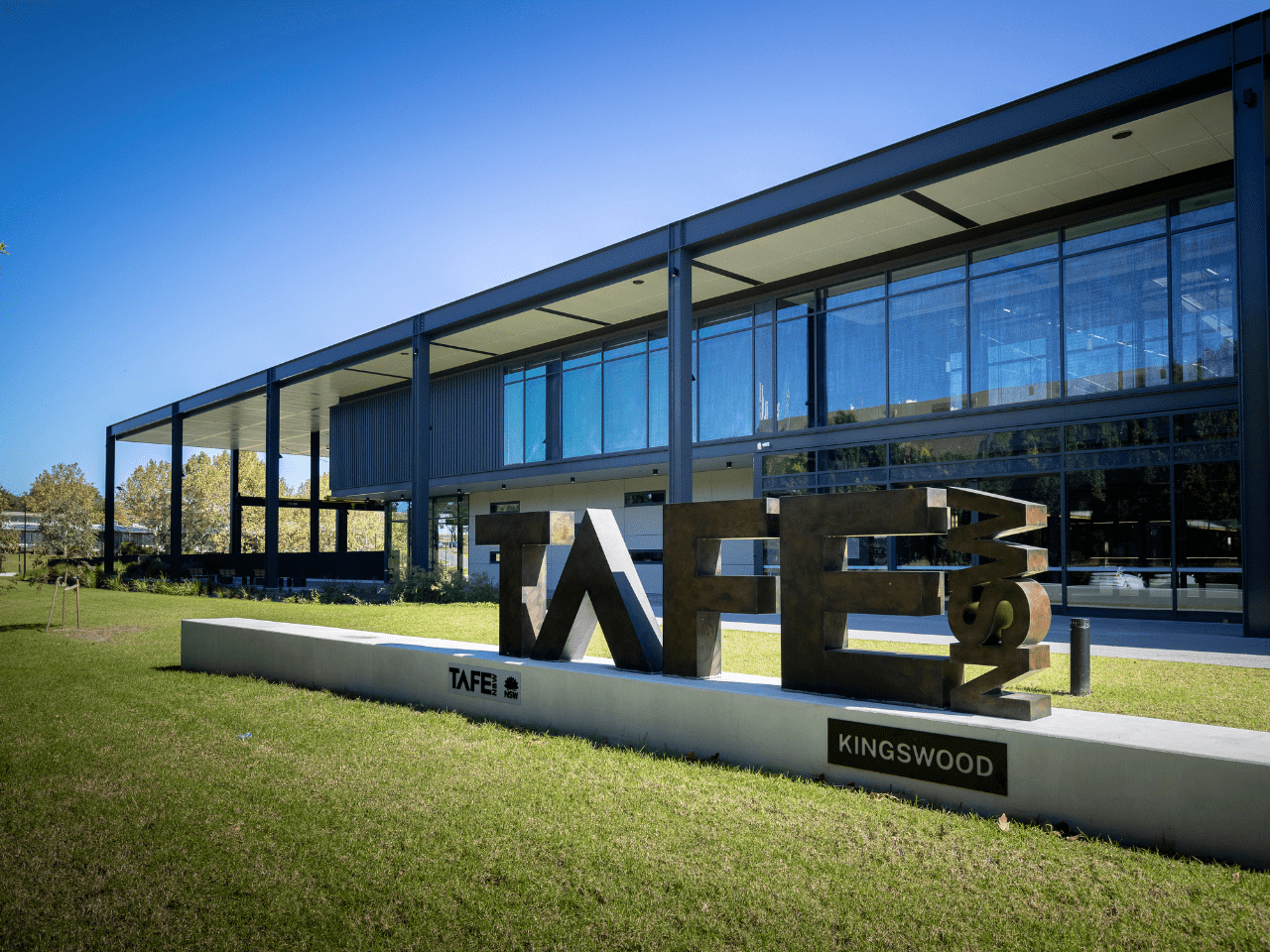

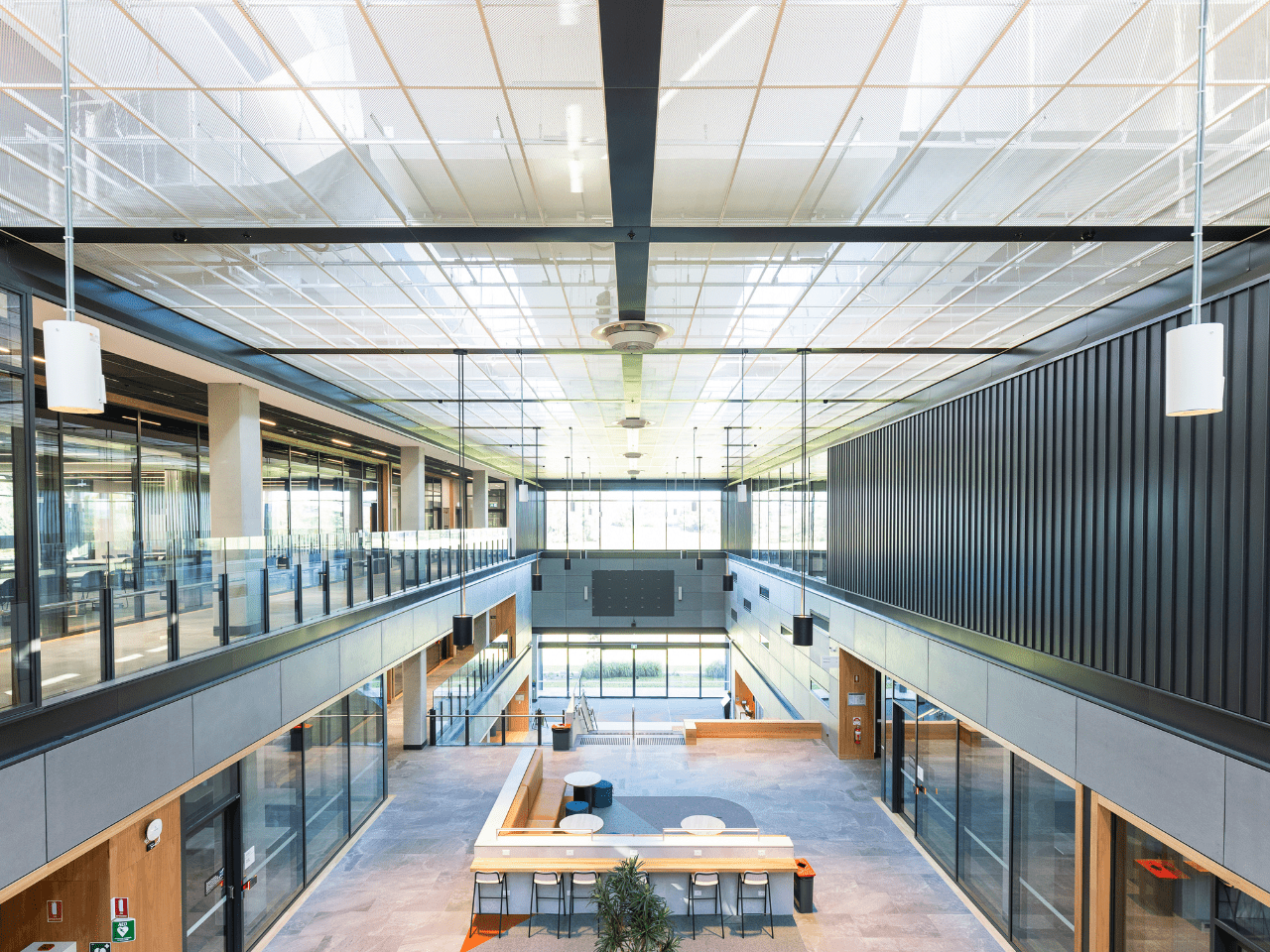

Characterised by precise standards of finish, durlum metal ceilings are widely used in diverse settings such as airports, railway stations, shopping centres, office buildings, schools, sporting venues and other outdoor structures.

Here are several architectural advantages that make durlum the best option for your bespoke metal ceiling:

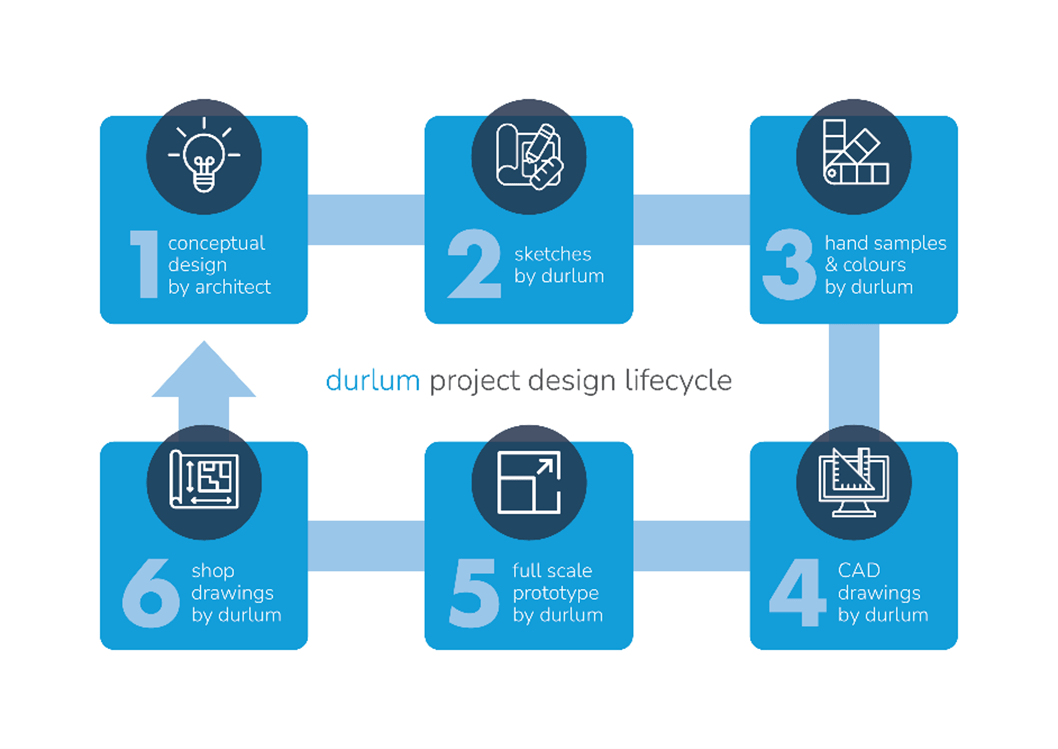

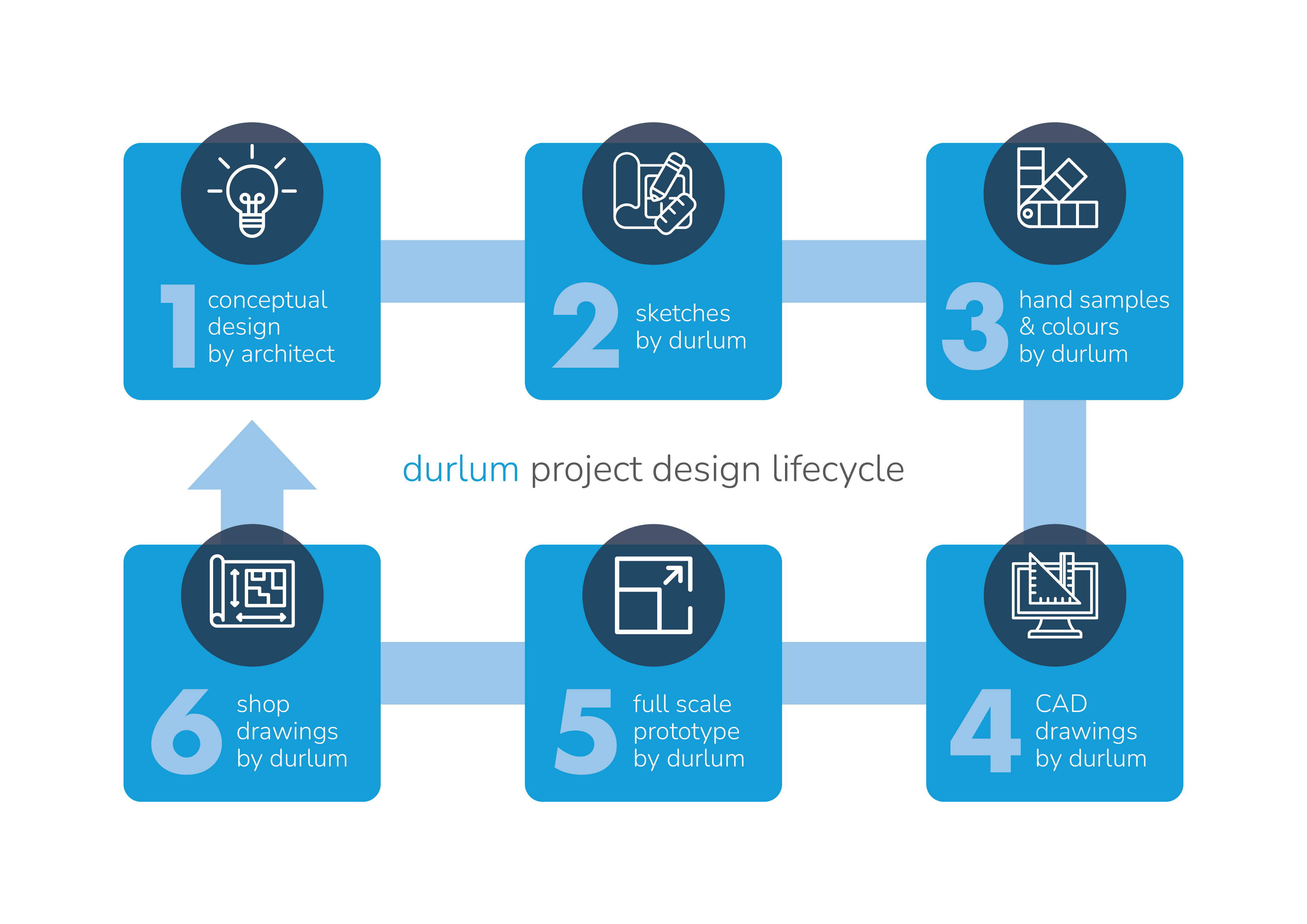

- Our unique durlum Project Design Lifecycle process ensures a complete in-house service from concept to completion, with a quick turnaround on drawings and samples.

- Streamlined design aesthetics available in linear, modular, curved or sculpted layouts and can be customised to achieve your design vision

- Resistance to humidity, mould and mildew growth

- Accessibility for easy cleaning and maintenance

- Fire-resistant and compliant with Australian standards

- Smooth integration of electricals, cabling, lighting, heating, cooling and more

At Network Architectural, we also provide you with complete peace of mind when it comes to using this bespoke metal ceiling product.

In fact, all durlum metal ceilings we supply are backed by a 10-year warranty. We also make sure you get the knowledgeable support and technical expertise you need both from our local ceiling specialists and durlum’s global team.

Network Architectural can bring your design vision to life with our bespoke metal ceiling solutions

Do you have some great ideas about incorporating bespoke metal ceilings, yet are unsure about how to initiate the process?

At Network Architectural we can help. Our in-house team will walk you through every stage from concept to completion, to ensure that your vision is achieved.

Our detailed durlum architectural design process will bring your vision to life and exceed your expectations.

- We begin our process by reviewing your conceptual design.

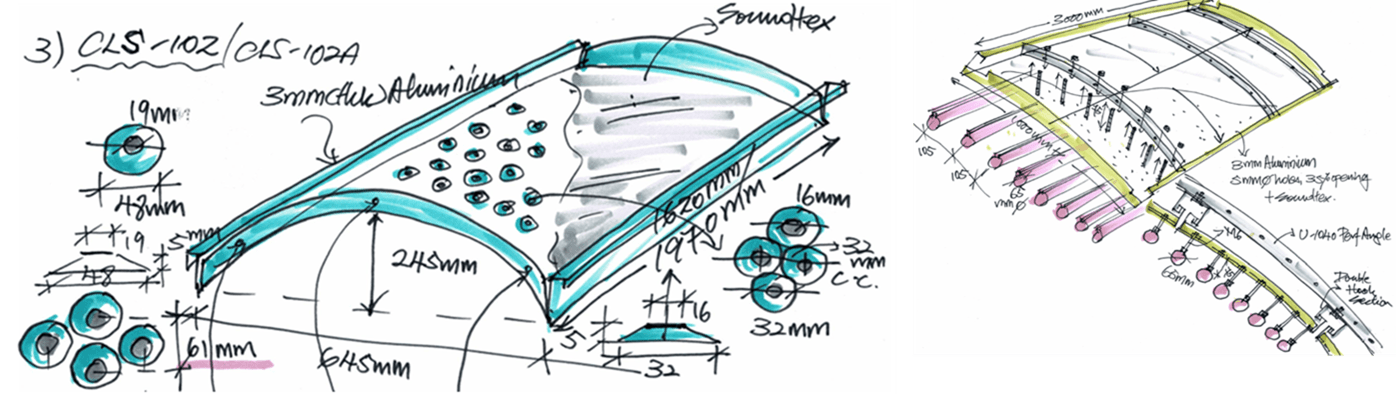

- Our durlum design team then creates a more detailed hand sketch to bring this concept to life, giving you a glimpse of what your project could look like.

- To further refine the details, we provide hand samples and a wide array of colours, allowing you to select the perfect combination to match your design.

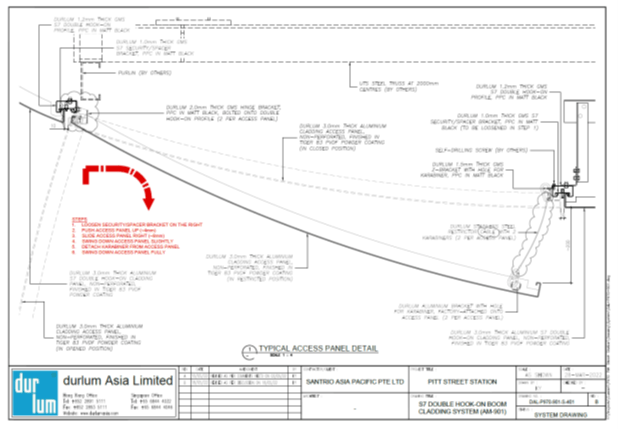

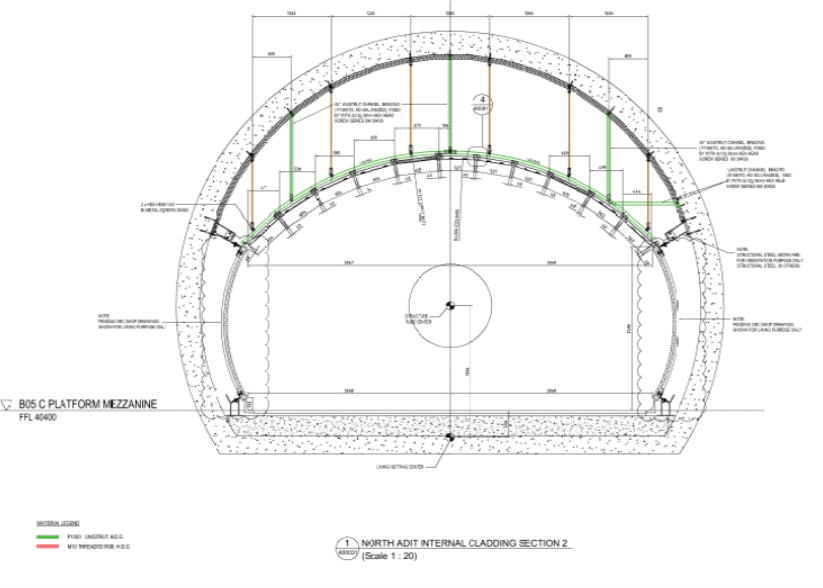

- Once the sketches are approved, our experts create precise CAD drawings, ensuring every element of the bespoke ceiling design fits seamlessly together.

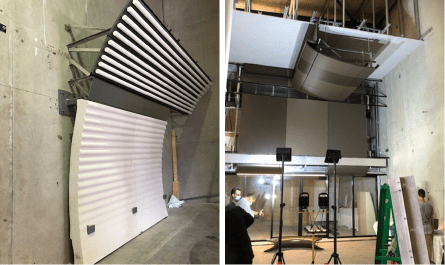

- We then offer an option to take your design to the next level by constructing a full-scale prototype, allowing you to experience the end result.

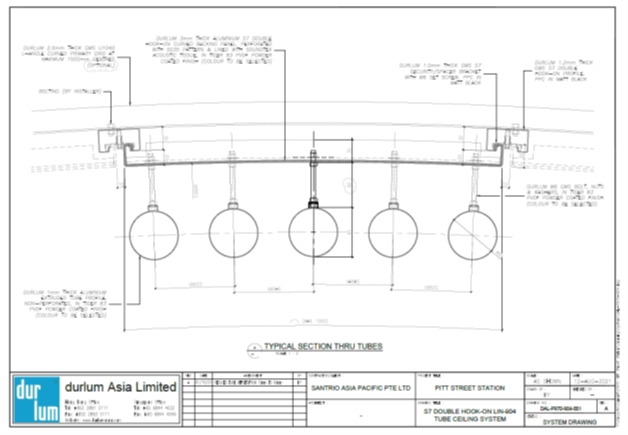

- Finally, our experienced team at durlum produces meticulous shop drawings, guiding the construction process and bringing your project to life so that it is easy to sign off on before going into production.

At Network Architectural, you can trust that we’re passionate about our work and your project.

We listen, learn and always strive to improve and innovate to help you find the best solution for your specific designs, specifications and project requirements.

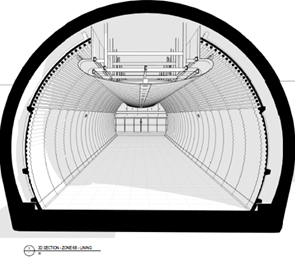

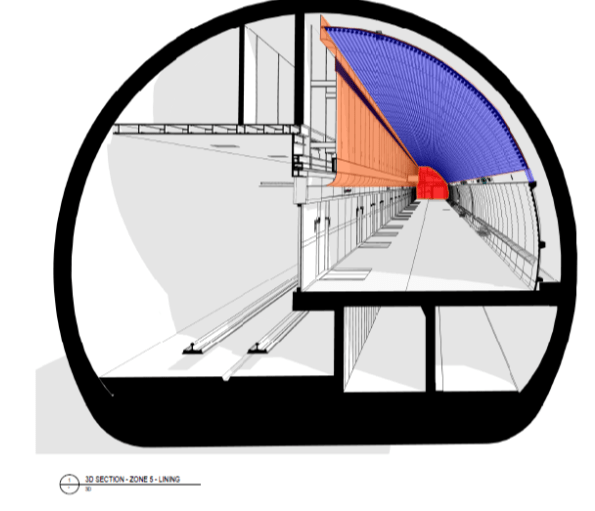

Have a look at how we have implemented our durlum architectural design process for the Pitt Street Metro Train Station project.

[PHOTO – Pitt Street Station | Conceptual design]

[PHOTO – Pitt Street Station | Sketches by durlum]

[PHOTO – Pitt Street Station | CAD drawings]

[PHOTO – Pitt Street Station | Prototypes]

[PHOTO – Pitt Street Station | Shop Drawings]

[PHOTO – Pitt Street Station | Progress Shots]

[PHOTO – Pitt Street Station | Completed photos]

[PHOTO – Pitt Street Station | Renders]

Ready to feature a bespoke metal ceiling in your next project?

Whether you have more questions about bespoke metal ceilings or are looking for the right ceiling solution for your project, we’ve got you covered.

Just reach out to us – our expert metal ceiling team can help you achieve the results you’re after.

As always, it’s best to seek the expertise of a trusted and well-established Australian ceiling supplier that can provide you with the highest standard of products.

At Network Architectural, we look forward to becoming your trusted partner for all your building and construction projects!