Background

A symbol of great historical, political and societal significance, NSW Parliament House consists of a heritage-listed complex of buildings where the Parliament of the state of NSW resides. Located on the east side of Sydney’s Macquarie Street, the edifice has recently undergone a refurbishment by renowned architectural, interior design and urban design practice, Brewster Murray.

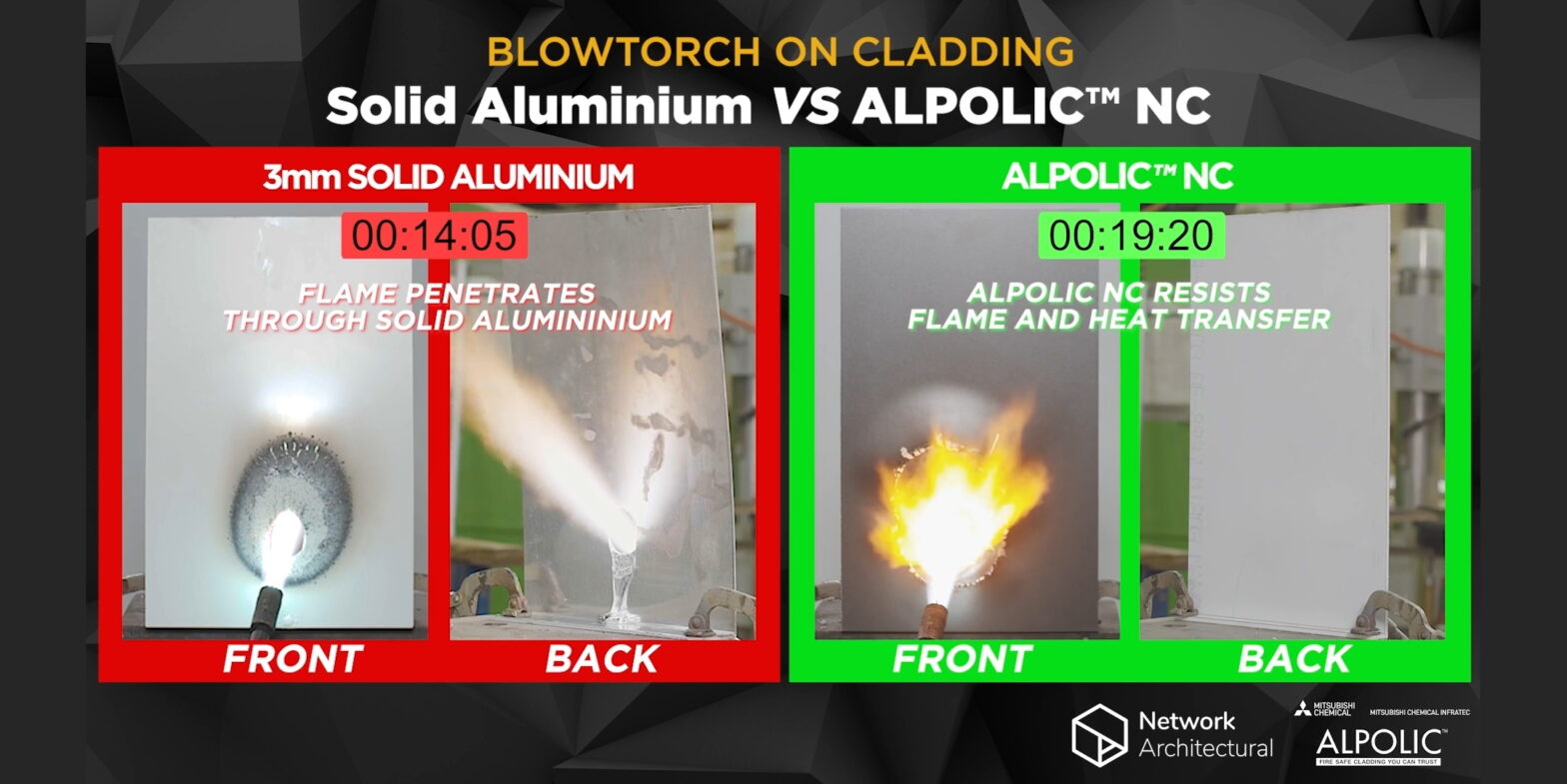

As part of the project, the highly flammable and dangerous polyethylene filled combustible cladding on the rooftop had to be replaced with a safer, non-combustible alternative. “That combustible cladding was actually on the list of products banned by the New South Wales Government,” explains Omer Pervanic, the Managing Director of OP Projects Pty Ltd. “So it was really important to find a solution for that.”

Challenges

Apart from bringing the historical building up to standard with a non-combustible product, it was paramount that it had an appropriately engineered substructure, to accommodate the range of weather conditions the roof surface is naturally exposed to throughout the year.

Omer adds that the rooftop space posed quite a challenge in terms of access and safety. “There was no edge protection for our team, so we had to work with life lines and static lines to install the panels,” he describes. As a result, it was paramount for the new cladding product to require little to no maintenance, in order to minimise the need to operate within this difficult to access space.

Lastly, particularly because of the representative character of the facility, it was important for the new product to fit in with the overall aesthetic of the exterior, and match the existing colour of the building for a stately, consistent look.

Solution

ALPOLIC™ NC/A1 from Network Architectural is the world’s safest aluminium facade product, and the only composite material that has been classified for the highest fire protection class A1, according to the European fire protection standard EN 13501-1.

Widely considered the golden standard in non-combustible cladding, the product was a natural fit for this project – and with the largest selection of colours and finishes on the market available, matching the aesthetic of the building exterior wouldn’t be a problem.

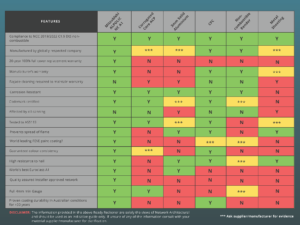

After completing a robust feasibility process to remove combustible cladding, as part of the recent re-cladding of all the Telstra Data Centres in Australia, Brewster Murray compared fire test results and performance data on solid aluminium, corrugated core bonded Laminates and the ALPOLIC™ NC/A1. The superiority of the Network Architectural product was clear.

“The Network Architectural product is 100% non-combustible,” Omer says. “It’s passed a range of fire tests – and offers robust documentation to support that. Alongside our recommendation to choose the product we supplied the supporting documentation to the client. As a result, ALPOLIC™ NC/A1 was accepted as part of the NSW Parliament House works.”

On top of the outstanding fire safety and durability credentials, ALPOLIC™ NC/A1 offers a 20 year full cover warranty, which includes rectification costs for material failure. And due to the superb Lumiflon FEVE paint technology, which makes the cladding exceptionally resistant to weathering, UV radiation, corrosion and colour fading, ALPOLIC™ NC/A1 requires virtually no maintenance. “The product is top quality,” Omer enthuses. “And Network Architectural were very responsive. We ordered the product and it was ready to pick up the next day.”

Omer adds that before ordering the panels, his team had to go through the process of inhouse shop drawing, during which the architect and designer on the project asked some technical questions about the bending, cutting and folding of the panels. “We consulted Network Architectural to understand how the product works, and how it reacts in those circumstances,” Omer says. “They were very helpful and provided a selection of technical charts that answered all of our questions.”

Click here to download a copy of this case study or for more information, please contact us.