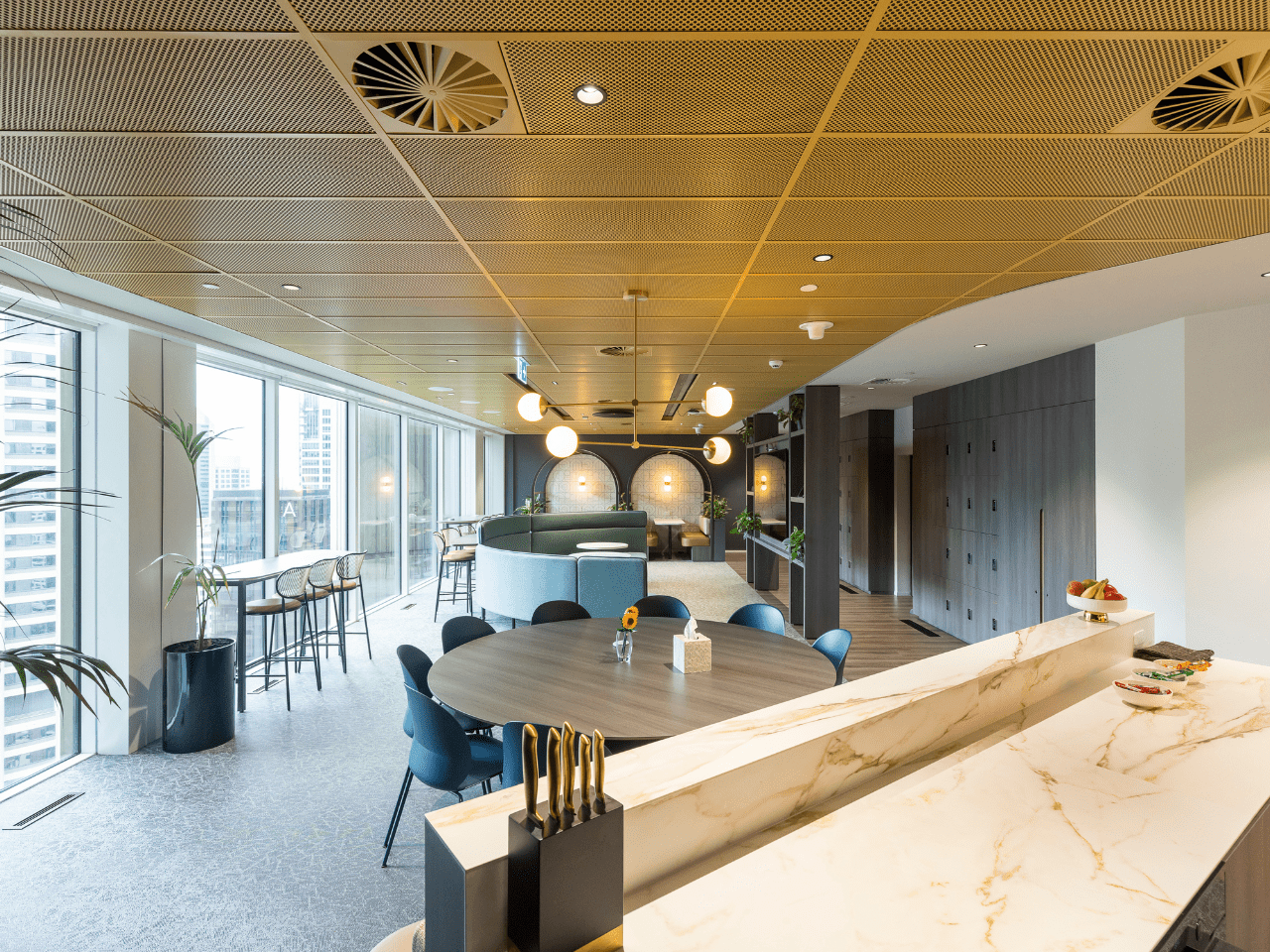

When Altis Consulting set out to transform their office into a premium, high-end workspace, every detail was meticulously planned to reflect luxury, innovation, and functionality. This ambitious commercial fitout, led by Komad, a Sydney-based expert in commercial fitouts and project management, and designed by studiobb, known for their human-centered approach to architecture, required a ceiling solution that would seamlessly blend aesthetics with performance. That’s where Network Architectural and durlum bespoke metal ceilings stepped in to deliver an exceptional result.

The Vision: Luxury Meets Functionality

The objective of the project was to remove the existing office fitout and create a high-end workspace that would impress both clients and employees. Studiobb, renowned for their focus on user experience and sustainability, envisioned a space that would evoke an emotional response while maintaining functionality and elegance.

“The brief for the design was to create a high-end office space, and the use of gold blended perfectly with the opulent feeling we were trying to achieve,” said Susie Bryden, from studiobb.

durlum’s Bespoke Metal Ceilings: A Key Design Feature

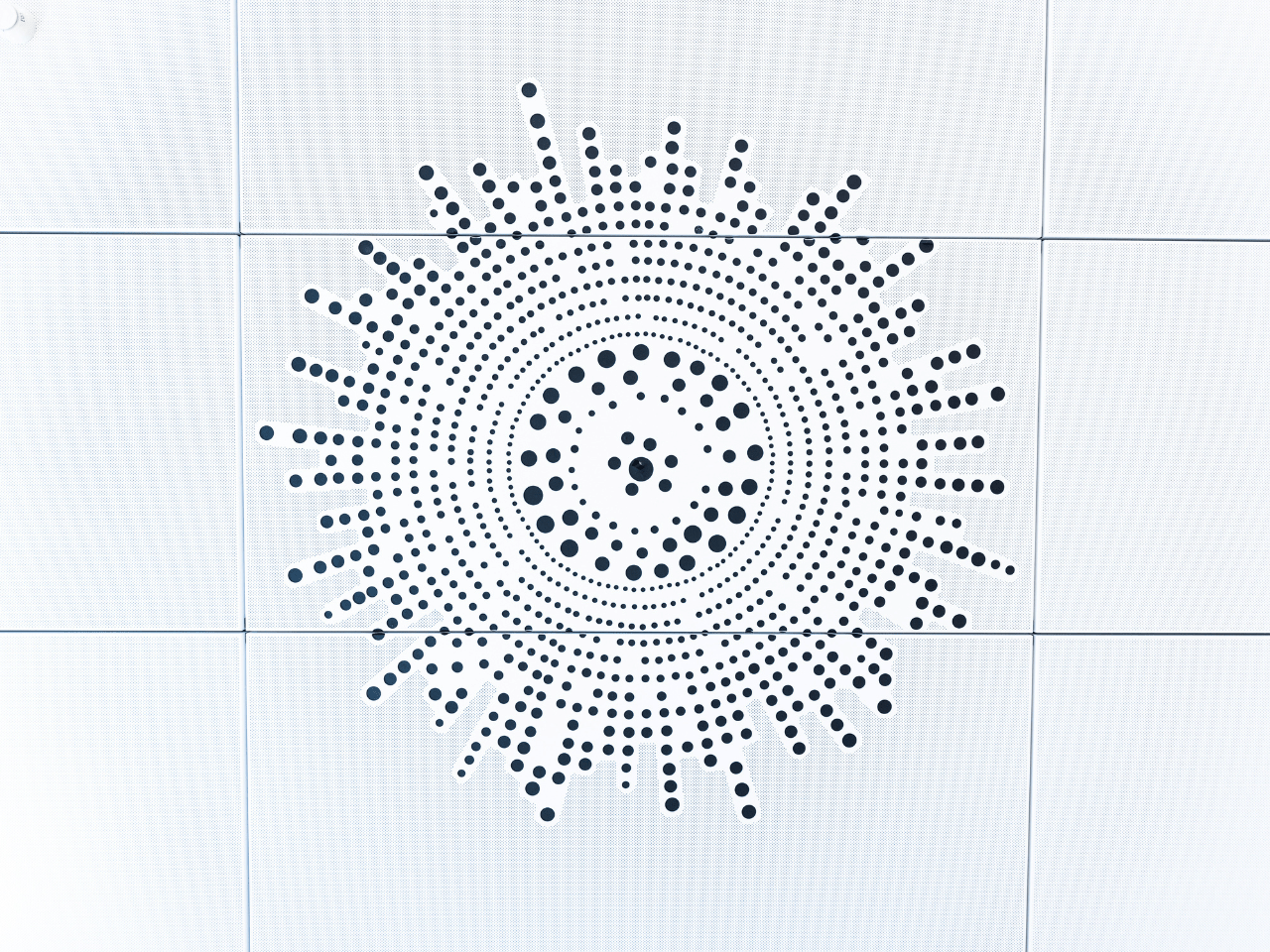

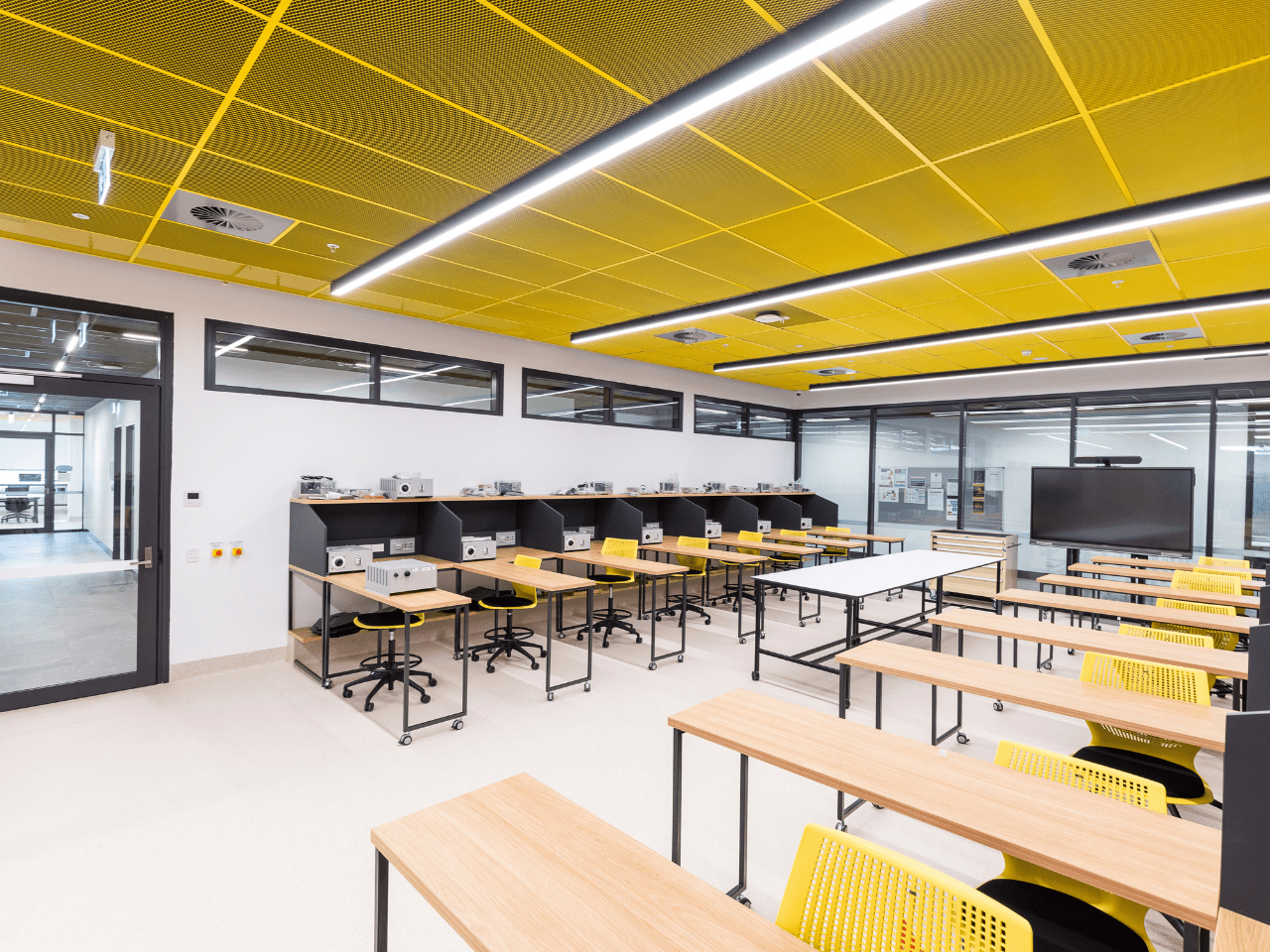

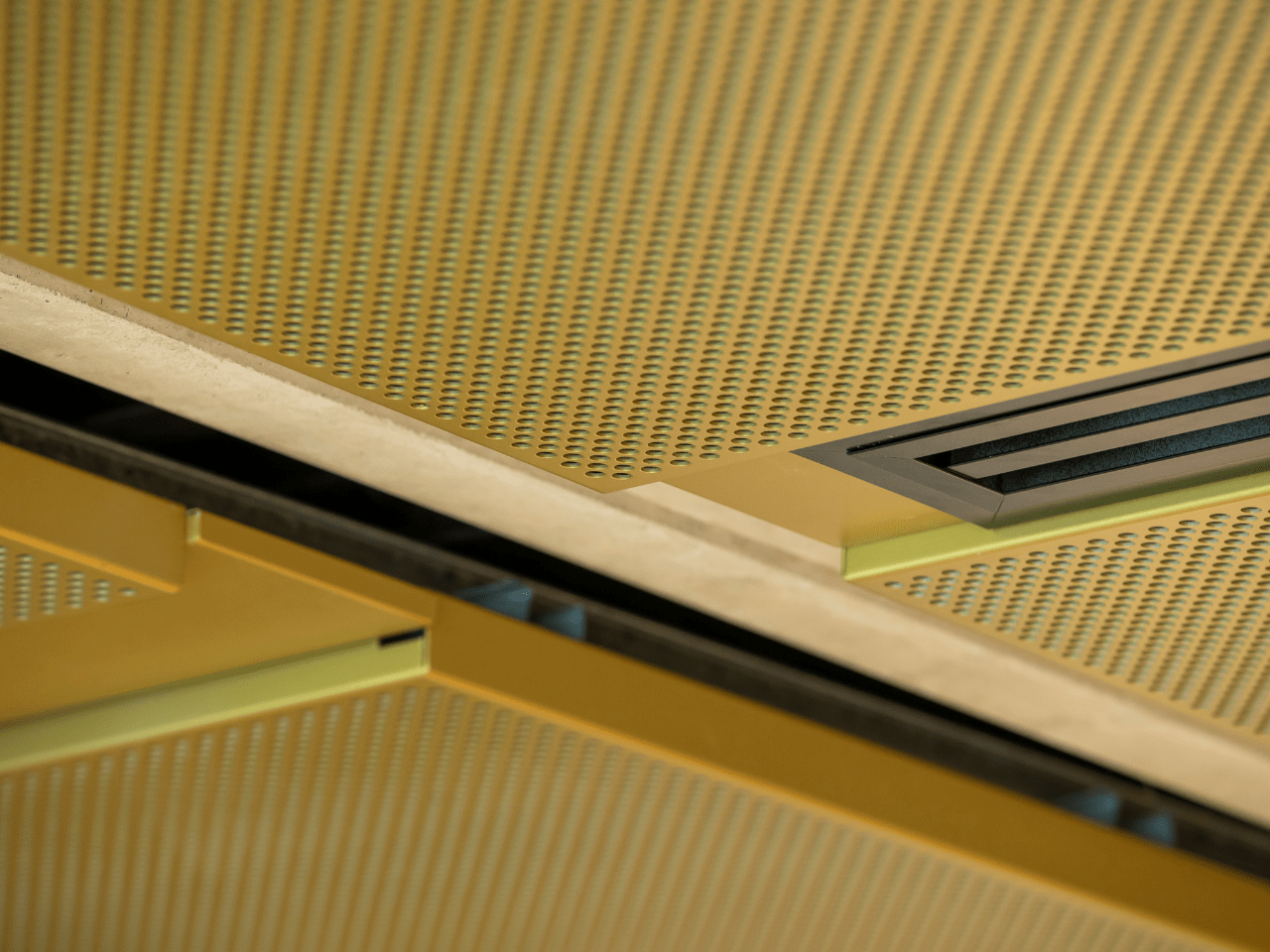

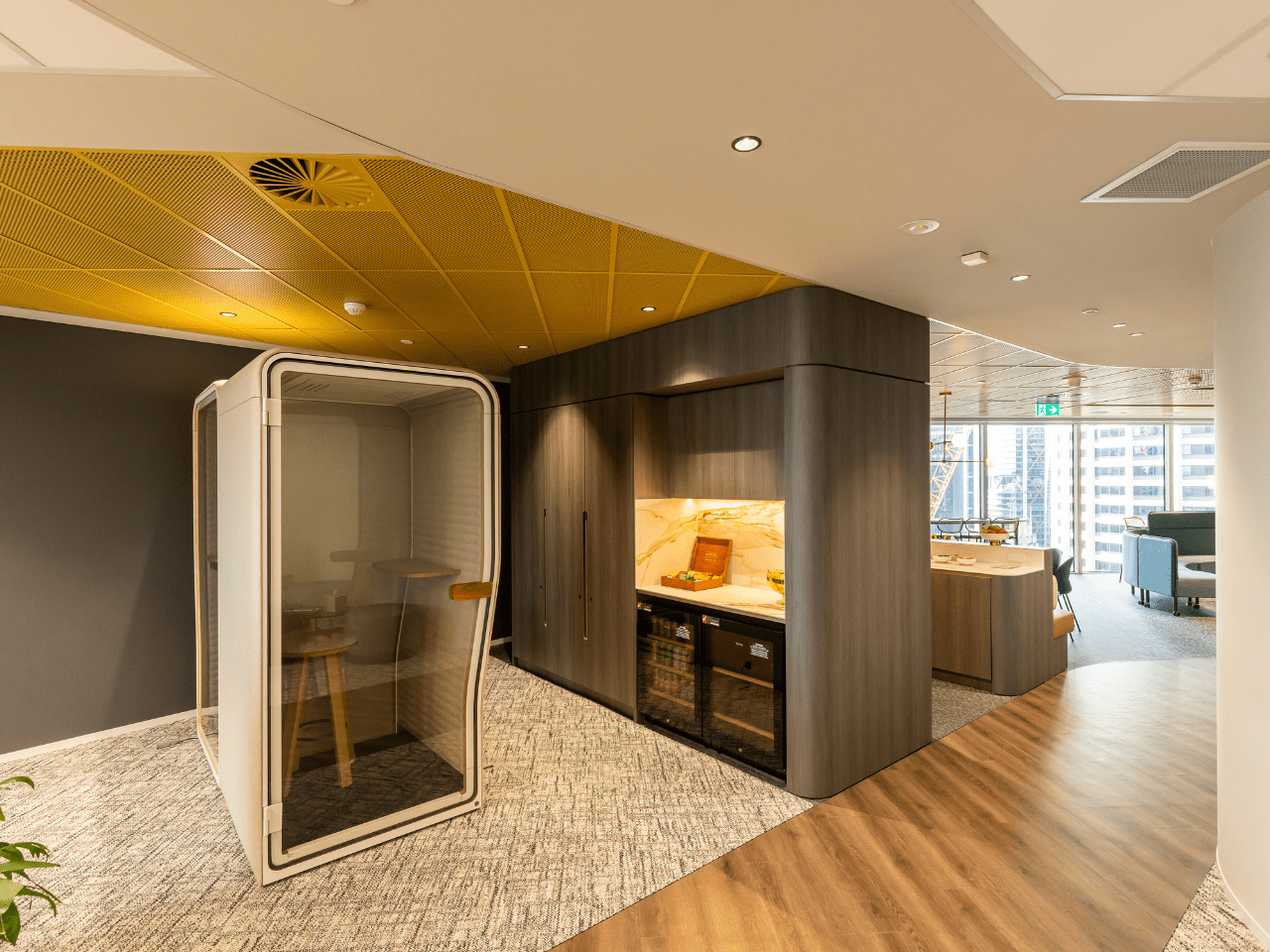

One of the standout elements of the Altis Consulting office was its main lobby ceiling, designed to be a visual masterpiece. The metallic gold perforated S7 ceiling panels from durlum were chosen to elevate the space, creating a stunning, contemporary aesthetic. Network Architectural worked closely with studiobb and Komad to ensure that the ceiling design met the project’s high standards.

Key features of the ceiling installation:

- Rapid Sample Turnaround – Within eight days, two samples were provided for sign-off, demonstrating durlum’s flexibility and efficiency.

- Precision in Colour Matching – The final ceiling panels were carefully colour-matched, ensuring a consistent and flawless finish.

- Customised Solutions – durlum adapted to evolving design requirements, including providing touch-up paint for a perfect final result.

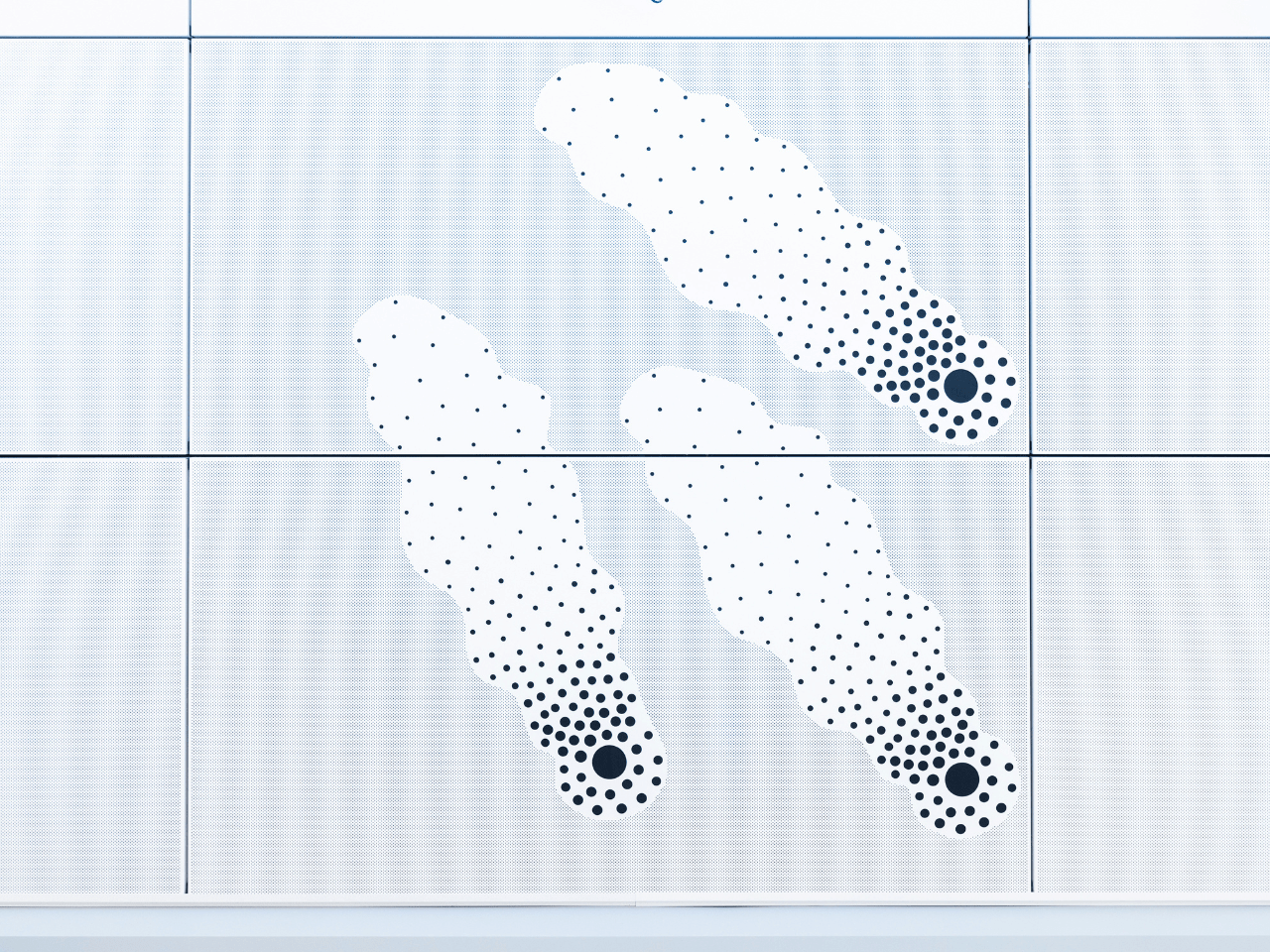

During the installation process, the original plan was to have exposed concrete sections between the gold perforated panels in the lobby. However, once installed, it became clear that the effect was not as visually appealing as anticipated.

Recognising this, Network Architectural and durlum swiftly adapted by designing and supplying bespoke infill panels that blended seamlessly with the rest of the ceiling. The result? A dramatic improvement in the overall aesthetics, proving Network Architectural’s commitment to delivering the best possible outcome for their clients.

“It was important for us to work with someone who understood the brief and had the attention to detail we required. Network Architectural delivered this, and their flexible and innovative approach made all the difference,” said Susie Bryden.

The Town Hall Space: A Hub for Collaboration

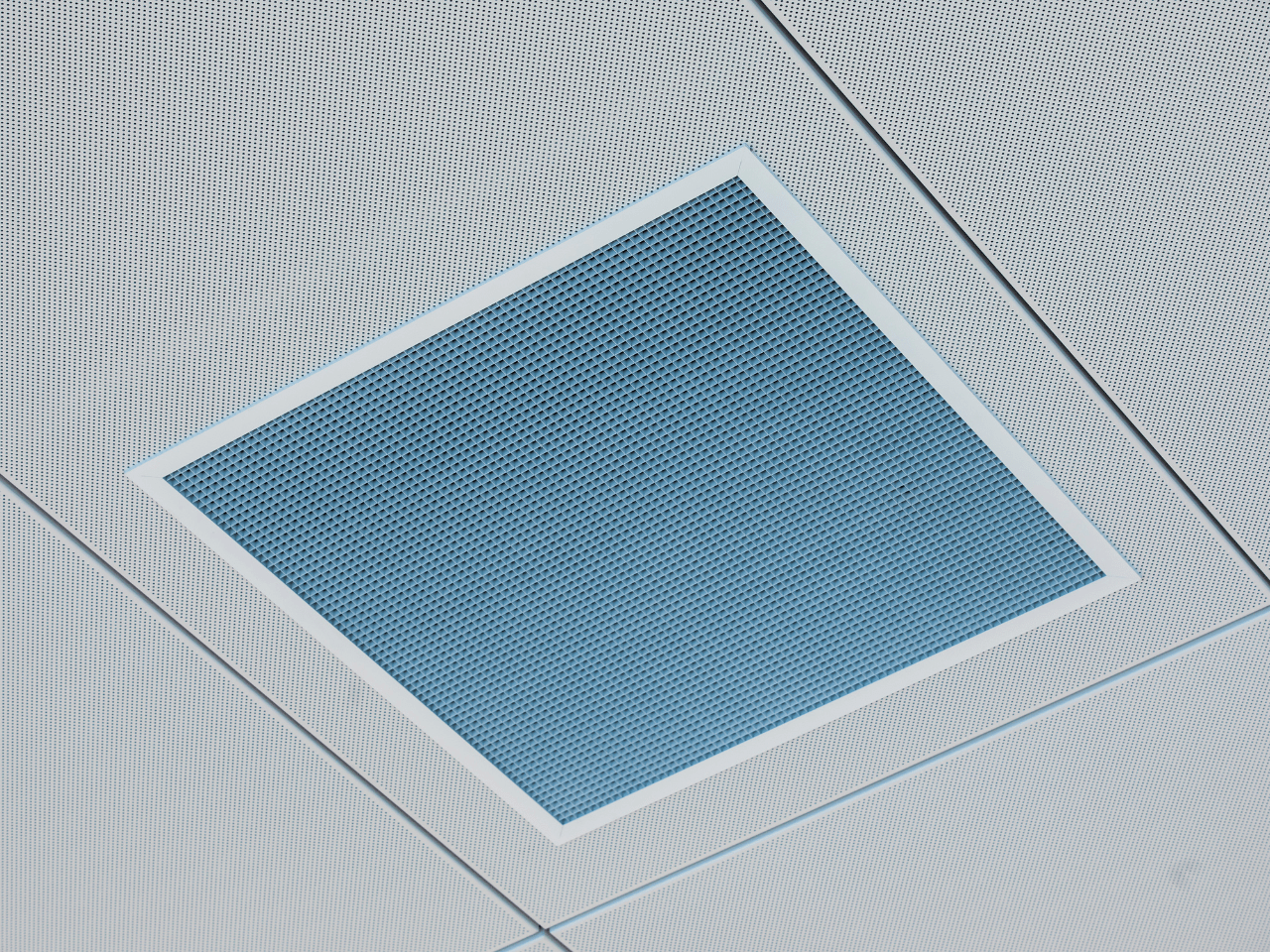

Beyond the main lobby, the “Town Hall” space was another crucial element of the fitout. Designed as a dynamic, open-plan area where employees could collaborate, socialise, and innovate, this space required a gold perforated ceiling solution that matched the lobby while also incorporating customised transition channels.

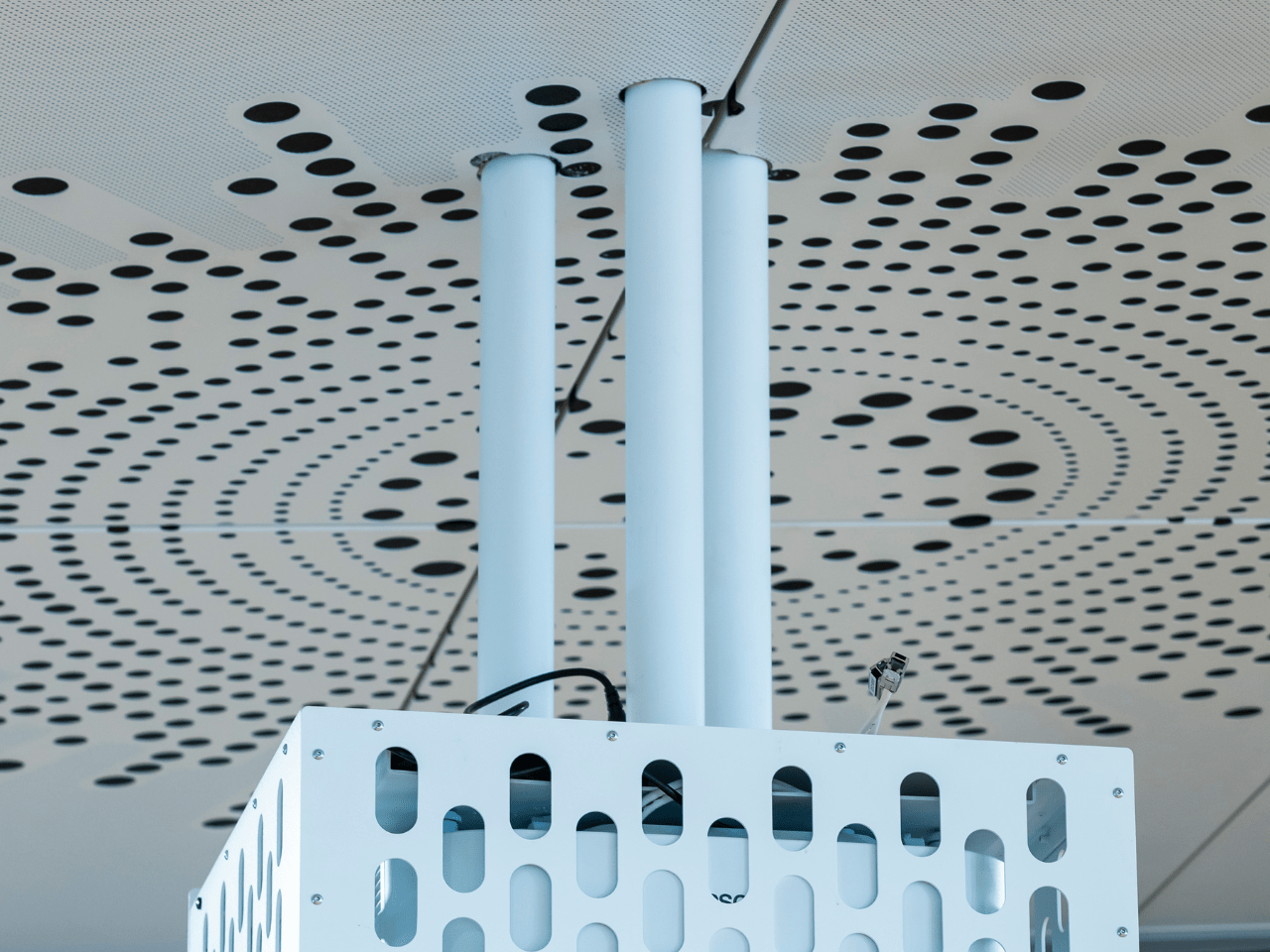

The biggest challenge? A tight plenum space that required a unique suspension solution. durlum engineered a custom approach, ensuring the transition between ceiling sections was both seamless and structurally sound, maintaining the premium aesthetic of the entire office.

“Creating a great environment for staff to work in is critical to productivity and well-being. The elegant, well-designed ceiling enhances the space, making it both visually striking and functionally effective,” said Joe Cacic, Forman from Komad.

The Power of a Beautiful Office Space

Research has consistently shown that workplace design directly impacts productivity and employee satisfaction. Studies suggest that:

- Natural and high-quality materials contribute to improved focus and well-being.

- Aesthetic office spaces foster creativity and innovation.

- Flexible, well-lit environments encourage collaboration and efficiency.

By investing in high-end materials like durlum metal ceilings, Altis Consulting has not only enhanced the look and feel of their workspace but also created an environment where employees feel motivated and engaged.

Why Choose Network Architectural & durlum?

Bespoke Design Expertise

Network Architectural specialises in tailor-made ceiling solutions, offering a wide range of standard and customised metal ceilings that blend durability with striking modern design. Whether it’s a complex installation or a high-end fitout like Altis Consulting, no project is too challenging.

Full In-House Service

From the initial design phase through to installation and post-install support, Network Architectural ensures consistency, efficiency, and quality throughout the entire process.

Quality Without Compromise

Working with durlum’s premium metal ceiling systems means quicker timelines, superior materials, and expert craftsmanship that stands the test of time.

End-to-End Project Support

Network Architectural’s ability to pivot and problem-solve in real time was a critical factor in the success of this project. Our commitment to delivering tailored solutions, maintaining high-quality service, and adapting to changing project needs makes a great choice for high end commercial fitouts.

The Altis Consulting office transformation showcases what can be achieved when exceptional design, expert craftsmanship, and premium materials come together. With Komad’s precision in execution, studiobb’s visionary design, and Network Architectural’s expertise in bespoke metal ceilings, the project has resulted in a workspace that is both sophisticated and functional.

For architects, builders, and designers looking to elevate their commercial projects, Network Architectural metal ceilings provide the ultimate combination of aesthetic excellence, durability, and flexibility, contact us today for your next project.