When a fire safety review was required for a large residential complex in Canberra, Risk Assessor Benjamin Hughes-Brown from Vortex Fire (formerly Ignis Solutions) investigated whether the current lightweight cladding was compliant and non-combustible. This is not an uncommon situation. A building may feature resort-like aesthetics but construction materials must stand up to Australian Fire Safety Standards.

This type of review requires in-depth analysis, starting with identifying the materials used on the building. “We would do a survey assessment on where the relevant materials are used and then run tests to identify whether it is non-combustible,” explains Benjamin from Vortex Fire. “If the material is proven to be unsafe and combustible, a total risk assessment is undertaken.”

“I’ve always found bodies corporate extremely proactive. They want the building to comply 100% to the Code – and not deviate – but they also need us to limit any disruption to tenants.”

Vortex Fire assessors work closely with project managers and bodies corporate to find the best solutions to replace existing, non-compliant material. This is always done by a fair and independent evaluation of products on the market that can be used wherever non-combustible materials are required.

“In the case of the Canberra apartment block, it came down to two lightweight cladding options,” said Benjamin. “In the end, the winner was not only compliant but had outstanding warranty and longevity.”

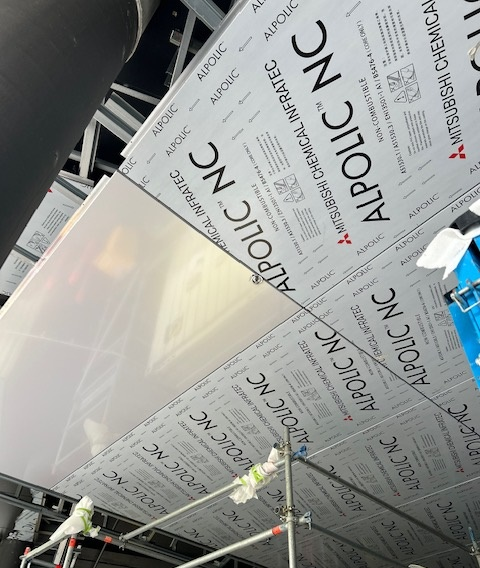

ALPOLIC™ NC/A1 from ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd was chosen for the apartment project for the following reasons:

- Ability to match existing colours so aesthetics weren’t compromised

- Warranty – The industry-leading full-cover unconditional warranty really shone through as did knowing that the warranty was backed by a globally trusted manufacturer and not a local distributor.

- Durability – The paint finish and longevity of ALPOLIC™ are exceptional and have been proven in Australian conditions for over 30 years

- Most importantly, the extensive local and international fire testing ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd has conducted on ALPOLIC™ NC/A1 well and truly exceeds the Code requirements.

|

|

“Beyond it being the right compliant non-combustible cladding, the process and expertise of Network Architectural, supplier of ALPOLIC™ NC/A1, has been fantastic,” said Ben. “The handling of the project was a testament to an expert understanding of complexities involved,” Benjamin said.

“We worked closely with Project Managers Dowse Projects, Wainwright Facades, and Vortex Fire to get the best possible outcome,” says Clint Gavin, National Sales Manager, Network Architectural.

“In the case of the Canberra apartment building, Project Coordination Australia commissioned Wainwright Facades to undertake the big job of removing the current flammable cladding and replacing it with the compliant, DtS non-combustible cladding ALPOLIC™ NC/A1. While initially several different cladding options were proposed, Wainwright Facades reiterated that ALPOLIC™ NC/A1 was ultimately chosen for its unrivalled warranty, quality, proven durability in Australia and compliance – having passed tests over and above what is required.”

Joseph Wainwright, Director at Wainwright Facades has worked in the industry for over 16 years. “While we have worked with ALPOLIC™ previously, this is the first time we have worked with ALPOLIC™ NC/A1. We found it very good to work with. All the guys in our fabrication workshop love it! It cuts well, we find it is easier on our drill bits, it is great to handle, and product performance is exceptional.”

Alex Shaughnessy, Project Coordinator from Project Coordination Australia had similar feedback on the product: “Because of the ease of manufacturing, cutting, and handling of ALPOLIC™ NC/A1, the project has run much smoother and more swiftly with short-term logistics. Because we are dealing with 330+ units and an existing client base, we’ve had to be reactive in some situations, and the ease of ALPOLIC™ to run through the machines has allowed us to respond to these issues easily.”

Alex couldn’t be happier with this result and is pleased that residents from the building have also openly commented on the finish of the product.

“Working with Network Architectural has been fantastic. I find them to be very accommodating and they know the building industry well and use this knowledge to make the process smoother,” said Joseph.

“Part of the requirement of the project was that the old cladding had to be removed and it needed to be recycled rather than go into landfill. Network Architectural was fantastic in assisting us with the best solution for this and offered a returning truck to Sydney to take the removed material back to the PanelCycle Recycling Centre. This ensured the project was better for the environment and streamlined the process.”

Network Architectural is the proud distributor of ALPOLIC™ NC/A1, the safest and most versatile aluminium cladding on the market. Its superior flatness and durability, and extensive selection of colours and finishes are all backed by rigorous testing for fire safety and compliance to meet Australia’s strict requirements and harsh weather conditions. ALPOLIC™ cladding comes with an industry-leading 20-year, unconditional, full replacement manufacturer’s warranty backed by ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd – no cleaning required! It gives both residents and developers reassurance that the building will stand the test of time.

Project Coordination Australia & Wainwright Facades both look forward to doing future remediation work with ALPOLIC™.

At Network Architectural, we are passionate about what we do. We listen, learn, and always strive to improve and innovate, helping our clients find the best solution for their specific designs and project priorities. Get in touch today with our highly skilled and experienced team for your next project.